Introduction

When you press rosin, the bag you use matters. A rosin bag plays a crucial role in determining the purity, flavour, and yield of your final product. With all the different micron sizes, bag dimensions and materials out there, it can get confusing fast.

That’s why this guide exists. By the end you’ll know what the numbers mean, how to pick the right bag for your material (flower, kief, hash, sift), and why starting with a standard bag is totally fine while you find your groove.

Whether you’re new to rosin pressing or looking to optimise your setup, this will be your go-to resource.

What is a Rosin Bag and Why Do You Need One

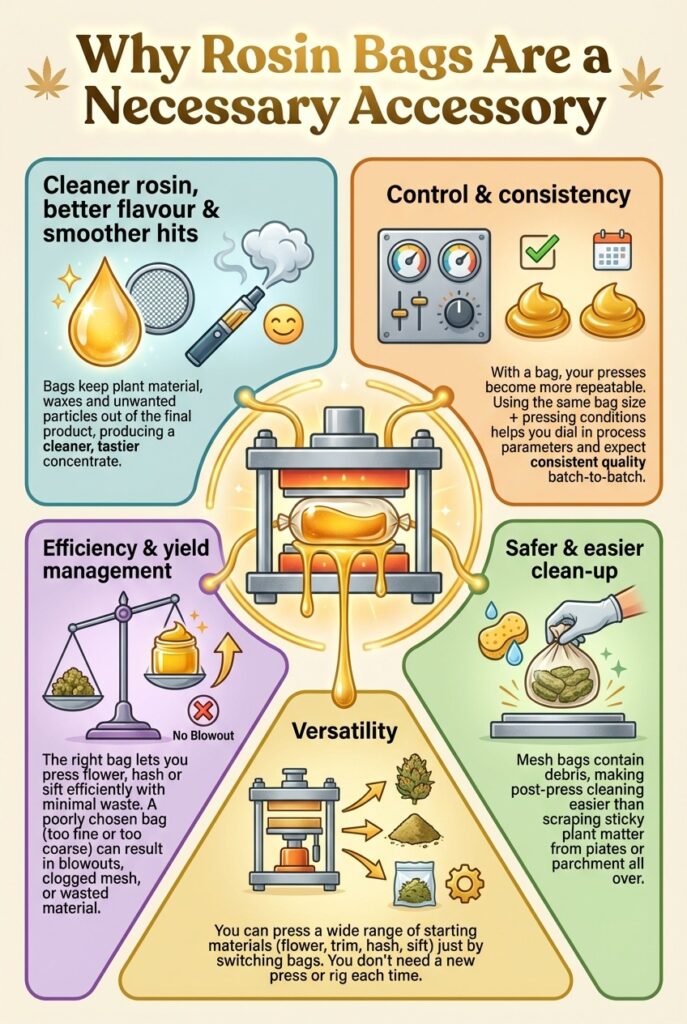

A rosin bag is a specially woven filter sleeve designed to hold cannabis flower, hash, kief or sift during pressing. Under heat and pressure, the oils (cannabinoids, terpenes and other resinous compounds) melt out of the material and flow through the bag’s mesh, leaving behind undesirables like plant matter, waxes, and fibre.

Without a bag, many unwanted particles would end up in your rosin. That translates to a harsher taste, darker colour, more plant residue, and a lower-quality end product. Using a rosin bag helps deliver cleaner, more flavorful, more refined rosin.

Nylon mesh is the standard material. It is heat-resistant, relatively flexible, and providing it’s food-grade, doesn’t impart off-flavours. Most quality rosin bag manufacturers (including Dulytek) use food-grade nylon and design their bags to tolerate high temperatures (often up to ~220 °C / 428 °F). Chill Kiwi rosin bags are a fantastic option of course!

Understanding Micron Sizes

The “micron” number on a rosin bag refers to the size of the mesh openings in the filter when new. A micron (µm) is one-millionth of a meter. A smaller micron number = finer mesh = smaller holes. A higher number = coarser mesh = larger holes.

What that means in practice: when resin melts during pressing, the mesh will let oil pass while blocking larger plant particulates. Finer mesh (low micron) means better filtering but slower flow and often lower yield. Coarser mesh (high micron) means faster flow, more yield.. But more chance for undesired material in the rosin.

Here’s a general breakdown used by many extractors:

Why these ranges: Hash, sift and kief begin already as concentrated collections of trichomes, they lack most of the bulky plant matter. Resin flows well through fine mesh without clogging. Flower (and trim) contains more fibrous plant material, so coarser mesh prevents clogging and blowouts while still letting resin flow.

A useful analogy: think of it like making coffee. Finer filters = smoother, cleaner coffee but slower flow. Coarse filters = more volume quickly, but more sediment.

Ultimately, the choice depends on what you prioritise: purity and flavour or yield and convenience.

How Big Bags Get: Dimensions & Capacity

Micron size isn’t the only factor the physical size (dimensions) of the rosin bag matters a lot too. This determines how much starting material you can press in a single press.

For example, Dulytek offers filter bags in many sizes. Their 120 µm bags are designed to fit standard press plates (e.g. 2″ × 4″).According to their site: those bags can accommodate roughly 7–12 grams of flower, depending on density.

Because of that, when choosing a bag you need to match:

- The press plate size – bag must be slightly smaller than the press surface but large enough to fully hold the material.

- The amount of material – larger bags = more flower/hash in one press.

- The micron mesh – fine mesh if you want purity, coarser for yield.

Tip: Many pressers buy sets of 5–10 bags in different micron sizes and dimensions so they can try different combos (small bag for hash, larger for flower, etc.).

Why Rosin Bags Are a Necessary Accessory (Even if It Looks Simple):

In short: a rosin bag is not optional — it’s a fundamental part of making quality solventless concentrates.

Dulytek Rosin Bags: What You Should Know

Since Chill Kiwi stocks awesome CK branded bags made by Dulytek, here’s what stands out from their specs and how to use them:

- Their 120 µm rosin filter bags are food-grade nylon, heat-resistant up to 220 °C (428 °F). Chill Kiwi

- Bags are available in standard press sizes (e.g. 2″ × 4″), which fits many small/medium hobby presses like the Dulytek DM800 available at chillkiwi.

- According to their specs: 120 µm bags hold roughly 7–12 g of flower (depending on density) which is a useful guideline for planning your presses.

- Because the bags are double stitched and made of nylon, they offer good durability under pressure. Dulytek recommends turning bags inside out before use (seam inside) to help prevent blowouts and ensure a smooth interior surface for resin to flow.

Using Dulytek Bags – Tips

- For a first press with flower using 120 µm, keep the load moderate (don’t overfill) — helps avoid blowouts especially on smaller presses.

- If you want cleaner rosin, consider pairing a coarser outer bag (e.g. 120 µm) with a finer inner bag (e.g. 90 µm or 75 µm) a kind of double-bag approach many extractors use to catch extra particulates while preserving flow. This is common in commercial solventless workflows.

- Always use clean parchment paper under the bag for the press plates, this helps collect the rosin cleanly and avoid sticking.

Choosing the Right Bag: A Quick Decision Flow

Here’s a simple flow you can use when looking at your material and deciding what bag to use:

- What is your starting material?

- Hash / dry sift / bubble hash / kief → go for fine mesh (25–75 µm)

- Flower / trim / shake → use coarser mesh (90–160 µm, e.g. 120 µm)

- Hash / dry sift / bubble hash / kief → go for fine mesh (25–75 µm)

- How much material are you pressing at once?

- Small presses or small amounts: small bag (e.g. 2″ × 4″)

- Larger batches: bigger bag (if your press can accommodate it)

- Small presses or small amounts: small bag (e.g. 2″ × 4″)

- What’s your priority?

- Cleanest, flavour-rich rosin → smaller micron (but expect lower yield)

- Maximum yield and easier flow → larger micron (but expect more plant matter)

- Cleanest, flavour-rich rosin → smaller micron (but expect lower yield)

- Experiment & adjust

- Start with a standard (e.g. 120 µm bag for flower)

- Tweak: try finer mesh for cleaner rosin, or coarser if yield is too low

- Consider double-bagging when pushing yield or handling very fine material

- Start with a standard (e.g. 120 µm bag for flower)

Common Questions & Concerns

Can I press without a bag?

Yes, some people do for small, quick presses. But skip the bag and you’ll likely end up with a darker, plant-matter-rich rosin, more like a crude extract than a clean concentrate. Using a bag helps separate resin from undesirables and preserves flavour and clarity.

Do I need different bags for different materials?

In practice, yes. Many experienced rosin makers keep a set of bags: fine mesh for hash/kief, mid-coarse for flower. Changing bags depending on starting material gives the most flexibility and best results.

Can I reuse bags?

It’s possible, but not always wise. Nylon mesh stretches under pressure, and repeated pressings can widen the pores or weaken seams. Also after a press, the pores often clog with resin/plant residue. If you want consistency and quality, many recommend using new bags regularly, especially if you target high purity.

What about blowouts (bags bursting under pressure)?

Usually caused by overfilling or using a mesh that’s too fine (which restricts resin flow). To avoid blowouts, don’t overpack, ensure material is evenly distributed and not tightly compacted. Make sure you choose a mesh size appropriate to your material. Double-bagging with a coarser outer bag is also a common safety step.

Final Thoughts: Don’t Overthink It!

Rosin bags might seem intimidating when you first look at the microns, sizes and trade-offs. But once you grasp the basics (fine mesh for hash/sift, coarser for flower, matching bag size to your press) it becomes straightforward.

If you’re new: a 120 µm bag for flower is a great starting point. It’s forgiving, yields well and lets you get comfortable with pressing. Later, you can experiment with finer mesh for hash or sift rosin if you want cleaner, tastier results.

And if you’re stocking Chill Kiwi bags, you’re working with quality gear. Food-grade, heat-resistant, and designed to fit standard presses. Use them right, and rosin pressing becomes less about guesswork and more about craft.

Press smart. Start simple. And let the materials do the talking.